Mini-Metallurgical Plant and 600,000 TPY Rebar Rolling Mill | Section Mill for Sale

The Minimill plant is composed of Melting & Refining shop

FastArc TM AC 70 t tapped steel

Ladle Furnace LF 70 t

Single-tank/single-cover VD/VOD station

FTP for EAF & LF primary and secondary fumes.

Melt shop auxiliary facilities

Continuous Casting Plant:

3-strand Danieli FastCast TM billet continuous casting machine

Rolling Mill:

80-t/h (or 100-t/h in hot charge) Bar and Light Section Mill

70-ton Ladle Furnace (12/14 MVA transformer).

70 ton VD/VOD station, single-tank, single-cover type.

Raw material handling/charging system for EAF,LF and VD

Fume Treatment Plant for primary and secondary fumes for EAF and LF E C B

The Meltshop:

A -Arc EAF 70-ton tap weight (64/74 MVA transformer), 5.3-m shell dia, equipped with the latest generation of wall-mounted oxygen/carbon injectors. The casting of specialty and stainless steel ingots

B -70 ton Ladle Furnace (12/14 MVA transformer).

C -70 ton VD/VOD station, single-tank, single-cover type.

D - Raw material handling/charging system for EAF, LF, and VD

E - -Fume Treatment Plant for primary and secondary fumes for EAF and LF

F - 3-strand, 9-m-radius FastCast Continuous Casting Machine, for high-speed casting of 130x130, 150x150,180x180-mm quality billets. Direct connection to the rolling mill reheating furnace, for hot-charging operation

PLANT CAPACITY: 500,000 tpy in cold-charge mode(*) Up to 600,000 tpy, in hot-charge mode

STARTING MATERIAL: Billet 150 x 150 x 12,000 mm

180 x 180 x 12,000 mm Weight 2,000 kg and 3,000 kg

STEEL GRADES: Low carbon, concrete reinforcing, low/medium alloy steels

FINISHED PRODUCT: Rounds (RB) from 16 to 50 mm dia

Deformed Bars (DB) from 10 to 40 mm dia, 4- strand slitting on DB 10, 12 mm dia 2- strand slitting on DB 14, 16 and 18 mm dia

Squares from 14 to 40mm, Flats from 30x6 to 80x25mm; Angles(equal) from 30x3 to 50x7mm; C profiles form 4 to 5

FINISHING SPEED: Up to 12 m/s

PRODUCT TOLERANCES: According to Local and International Standards

FINISHED PRODUCT SUPPLY: Straight Bar Bundles Length 6,000 to 12,000 mm Weight 1,000 to 5,000 Kg

(*) Yearly capacity based on a 3 daily shifts working schedule

Reheating furnace: Walking Hearth type capacity 80 t/h (or 100 tph in hot charge)

Roughing Mill: 8 AC driven ESS compact cantilever stands 820/685/585 mm dia in H and V configuration

Intermediate Mill: 6 AC driven SHS housingless stands 475 mm dia in H and V configuration.

Finishing Mill: 6 AC driven SHS housingless stands 430 mm dia in H, V and H/V convertible configuration equipped with automatic quick-changing system

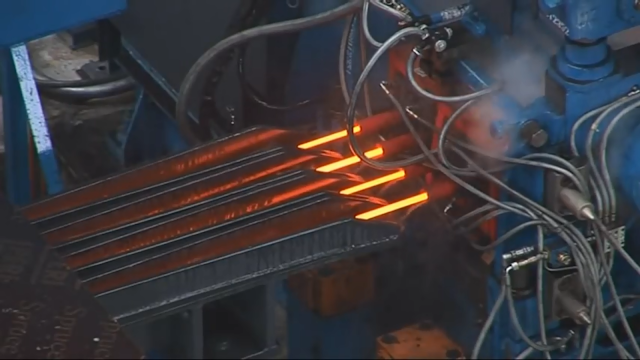

In-line QTB treatment for high tensile deformed bars

Cooling Bed: Rake type Dimensions 54 x 13m equipped with a water spray system

Finishing Services: CLS on-line start&stop Straightening and Cut-to-Length system (multistrand straightener and shear), bundling service, final tying and collecting services

DANIELI AUTOMATION fully integrated system for process technology and equipment control